Self-sufficiency in the Iranian oil, and petrochemical industry with nano-based alumina catalysts

Iranian companies have reduced reliance on imports in the oil and petrochemical sectors by producing nano-based alumina catalysts, leading to significant cost savings and progress toward self-sufficiency.

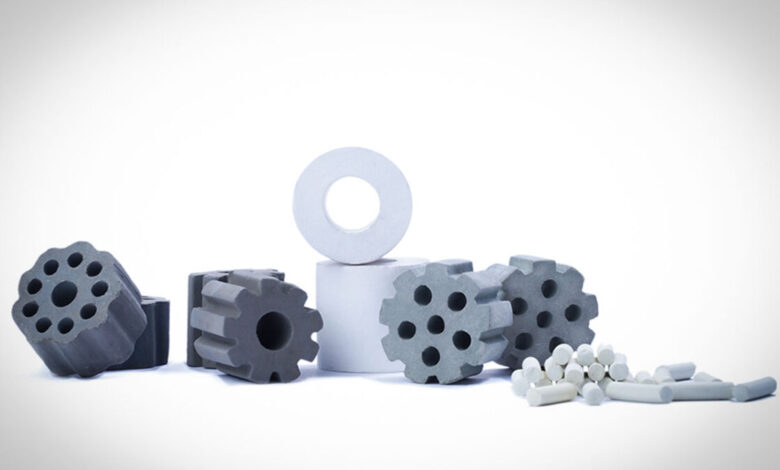

According to the information center of the Vice Presidency for Science Technology and Knowledge-Based Economy, Alumina catalysts, enhanced through nanotechnology, play a crucial role in processes like desulfurization, isomerization, and gasoline production.

By reducing particle size and increasing surface area, these nano-structured catalysts deliver higher efficiency, better performance, and lower production costs.

Several Iranian firms have successfully produced alumina catalysts with global-quality standards, addressing domestic needs while paving the way for exports.

These advancements are particularly vital under import restrictions, making alumina catalysts a strategic product in Iran’s industrial development.

The domestic production of these catalysts has not only decreased dependency on foreign suppliers but also saved significant foreign currency.

Furthermore, this achievement has created new job opportunities, with companies scaling up production and planning to expand into international markets.

The positive feedback from local industries underscores the growing demand for nano-structured catalysts, and their adoption is expected to rise in the coming years.

This progress marks a significant step toward industrial self-reliance and positions Iran as a potential exporter of advanced catalytic technology.